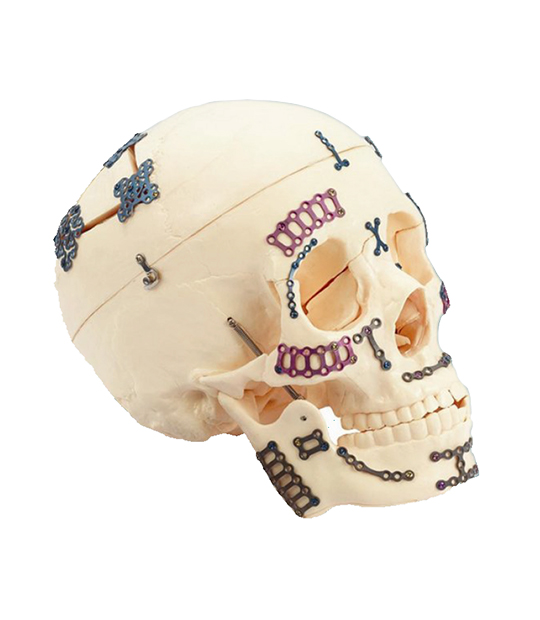

Our CMF range of implants are targeted towards the repair and reconstruction of the facial bones, namely, the mandible, maxilla, and the crania. The implants are made of the highest quality implantable grade titanium. We use the TiAl6V4 alloy conforming to ISO58322/3, which is rigorously tested against and conforms to international standards. This ensures peace of mind for our surgeons and patients.

We offer CMF implants in variants of 1.5mm, 2mm, 2.4mm, and 2.4mm recon. The plates, along with their screws are colour coded as per size. This is to enable the OMFS for quick navigation of the system on the operation table. The corresponding screws are available as self-drilling, non-self-drilling and screws for reconstruction plates.

Each individual plate is painstakingly machined on a CNC machine. Our production process is internationally competitive. The CNC machining gives a superior result for the product. It is observed that machining, instead of punching, eliminates any striations on the surface of the implant, thus reducing the chance of microbial load and infections.

The CMF range is provided with an instrumentation system that includes screw drivers for each size of screw, drills, plate cutters and plate benders. The instrumentation works in conjunction with the implants to facilitate hassle free surgery.

The implant has the following characteristics: